How a new factory decided on their own to increase the food production standards and how it affected the lighting design

BUCK has a long list of completed projects in industrial lighting. Our portfolio consists of pharmaceutical plants, food production plants, hi- tech, metal and other products. Each of the branches has their own particularities, and the conditions in the spaces, therefore the standards for production, is almost always different regarding hygiene or work environment (high humidity, extreme working temperatures, explosive substances manoeuvring etc.

What does HACCP standard mean for lighting applications?

Food production takes place in strict conditions regulated under international HACCP standard, prescribing the conditions for the whole production process, including lighting.

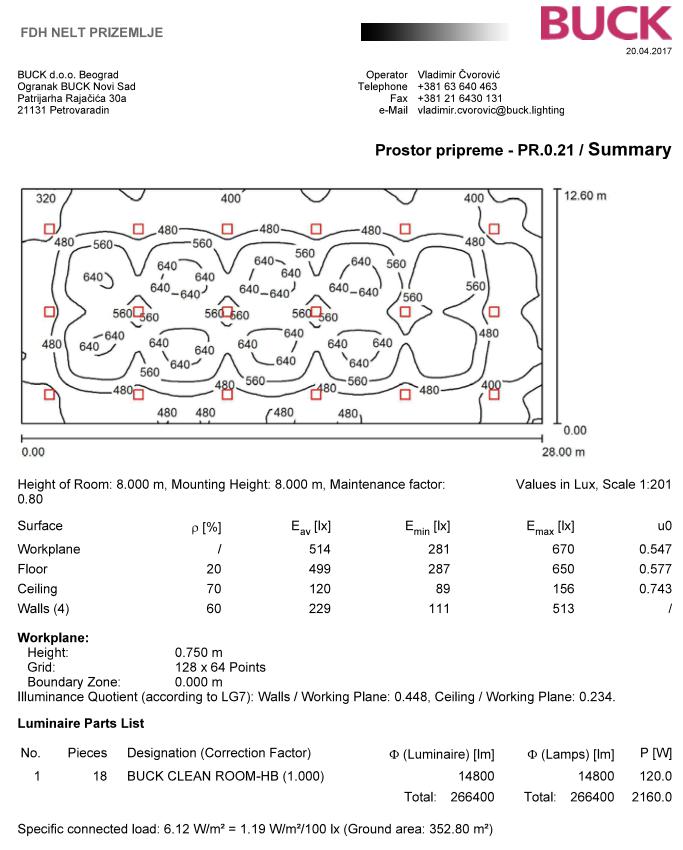

The standard workplace lighting for food production in work zones (according to standard EN 12646-1) requires 500 lx on work plane. The luminaires in food industry should have special construction, meaning smooth surface appropriate for maintenance. In case of breakage, the luminaires should be secured to prevent pieces of the fitting (diffuser, protector) from falling down and contaminating the production.

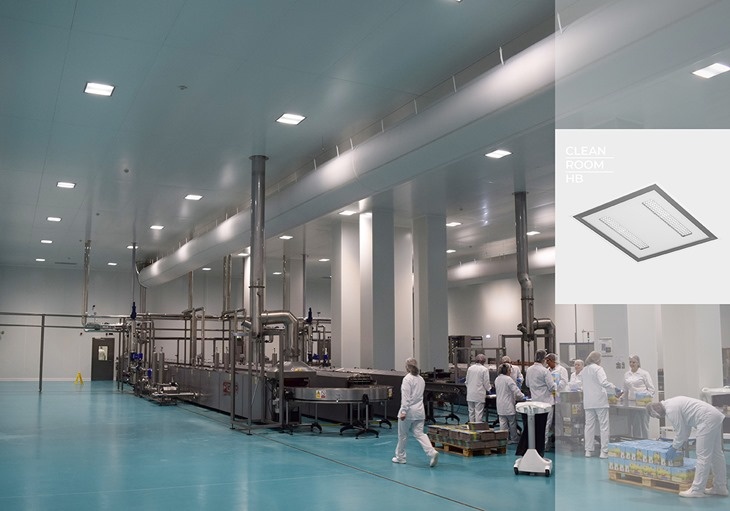

The investor (NELT group) has additionally raised the standards, having in mind the basic activity of the factory in Dobanovci- food production for the most sensitive population, children up to 6 years of age. Their requirements were that the production takes place in clean room spaces, which is the type of technology usually applied to operating theatres, pharmaceutical and semiconductor industry.

How is this project different from other food production plants?

From the lighting perspective, high ceilings (8m) are not typical for clean rooms, which are usually less voluminous. Our answer to this demanding project was the customisation of our existing Clean Room product to a new one, appropriate for this type of spaces, Clean Room HB.

The new product is the combination of our industrial and high- bay lighting experience, where the height of mounting requires different optics, and our experience in pharmaceutical industry regarding the luminaire construction. The request of the investor to have maintenance from above was also fulfilled.

This feature enabled maintenance without contamination of the clean room below, meaning shorter maintenance time and no time required to restore the space function, and no need for additional clean room certification.

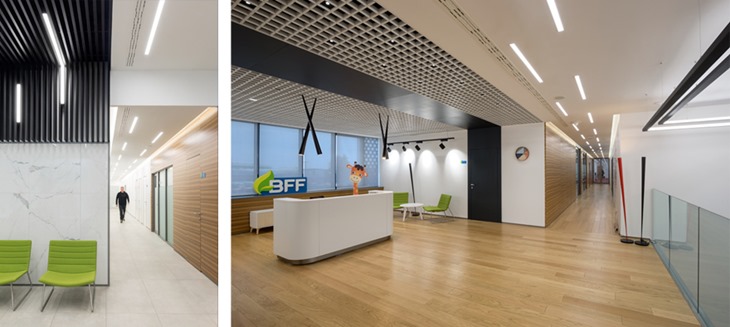

The whole project is a building of 15.000m2 with production and office areas. The offices were illuminated with BUCK’s luminaires SLIM LINE (custom version), AIRO, MATRIX, MICRO MD.

’We are very satisfied with the cooperation with BUCK, their professionalism, quality of lighting design and equipment delivered. We recommend them as a supplier that guarantees the quality in every aspect’- Baby Food Factory

After this successfully completed project, released in 2018, we maintained the cooperation with the same investor on projects that combine high- bay warehouses and office spaces ‘H5’ within the NELT property in Dobanovci (Serbia) and ‘H2’ within the property of NELT East Sarajevo (BiH).

It was a great pleasure for us to take part in this project, since the factory, from their opening till today, has succeeded to initiate the export expansion and build a recognizable brand, known for the high product quality.

Project information

Project name: Business building Baby food factory, Dobanovci, Serbia

Investor: NELT group

Project type: Business building with production plant and office space

Total surface: 15,000 m2

Luminaires used: CLEAN ROOM HB, SLIM LINE, AIRO, MATRIX, MICRO MD

Partner companies on the project: M+W, Termoinženjering doo