Clean Room Lighting

Over two decades of experience in illumination of clean rooms brought to life our entire Clean Room lighting range. Different in their use and requirements, our Clean Room lighting products, are applicable for clean spaces with ISO classes 1-9 and hygienic areas up to GMP classes A-C.

Other industry- specific lighting is available for explosive hazard environments, pharmaceutical industry, high- bay clean room production, to name a few. Browse through our products and find the one made especially for your clean room space, or contact us so we can help you choose the right model.

CLEAN ROOM LUMINAIRE BENEFITS

Ingress Protection

IP 65 from above and below, provides complete reliability of use.

Exproof Protection

For work environments with dangerous or explosive environments, we have provided Clean Room lighting products with Ex- proof certificate.

Reliability

Safe and reliable lighting equipment, with 5-year warranty.

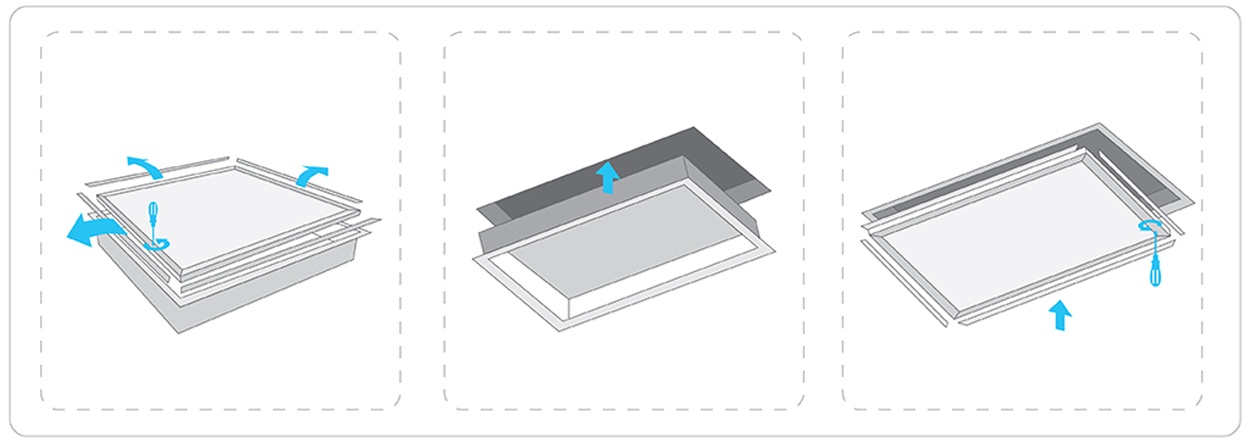

Mounting

Optimised for quick mounting and maintenance of Clean Room luminaires, saving time and mounting costs.

Optical accessories

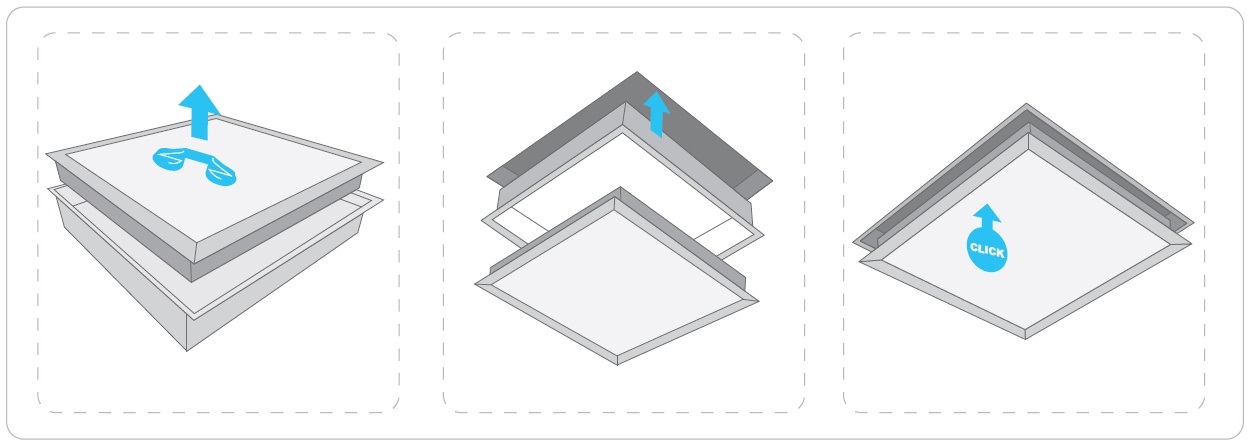

Optics and light sources specialised for each type of clean room: UGR<19, UGR<22, high-bay, SunLike, standard.

Efficiency

Energy efficient LED modules combined with optics to provide the maximum lighting level and quality of Clean Room fixtures. EM option, BMS integrable.

Verified technology

All components are of the latest technology by renowned producers, previously tested in a factory laboratory and approved by the technical staff.

Maintenance

Maintenance is available from below and above, depending on the technical requirements. Resistant to aggressive cleaning agents.

CLEAN ROOM FAMILY

High energy efficiency, long worklife, full visual comfort.

IP65

from above and below, for additional security.

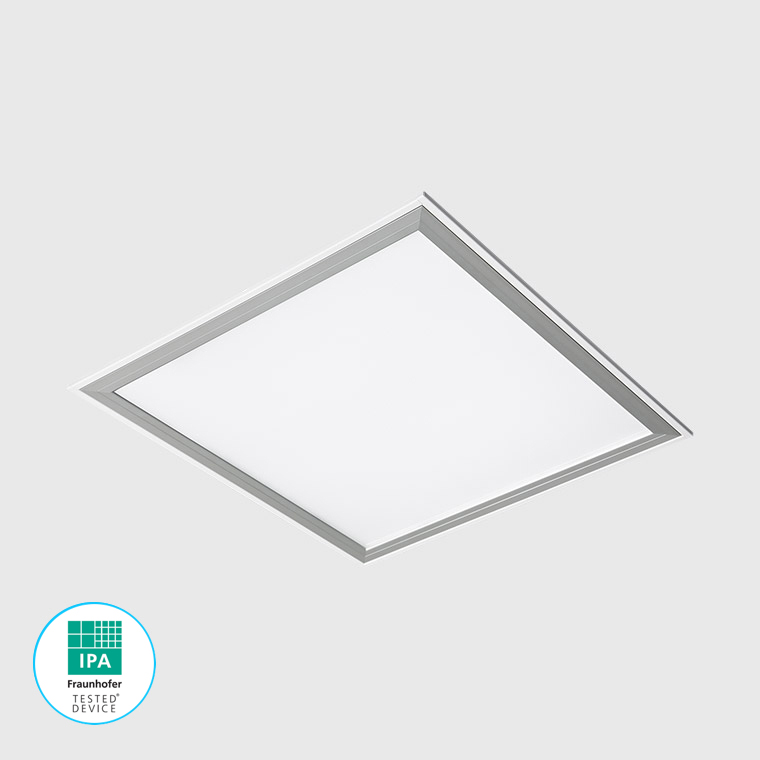

DOUBLE FRAME

ensures smooth surface and degree of IP65

MAINTENANCE

upon request from above or bellow

OPTICS

Latest

CLA multilayer optics, with highly transparent tempered glass protector, diffuser of microprismatic structure and opal foil, UGR<19. See more (mounting)

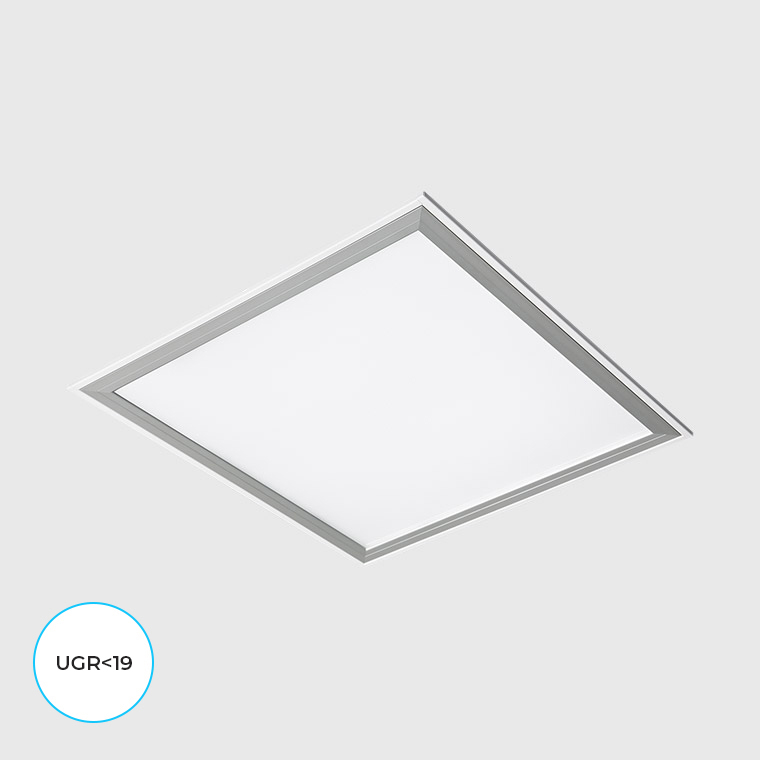

CLD opal diffuser providing diffused light. Latest generation LED modules and drivers. UGR<22. See more (mounting)

Standard

CDP highly transparent diffuser of microprismatic structure provides glare limitation and a uniform, diffused light. Opal foil provides a uniformly illuminated surface, without visible light sources. Protector of tempered glass provides a smooth surface for easy maintenance. See more (mounting)

DO opal diffuser, with the frame of extruded aluminium of a special construction, provides a high sealed degree of the luminaire, while forming a flat surface simple for maintenance. See more (mounting)

HOUSING

HOUSING is constructed of bended 0.8mm thick steel sheets. The parts are assembled by resistance spot welding and TIG welding. Final coating procedure includes degreasing, phosphatisation, washing and zinc primer coating, after which epoxy polyester powder RAL9003 (white) is applied and then polymerized at 180 C. The powder is used for surface protection of luminaires for medical use, as it is resistant to aggressive cleaning agents due to its bactericidal characteristics.

Maintenance is available from below and above, depending on the technical requirements. Resistant to aggressive cleaning agents.

Our clients said…

Production

’We are very satisfied with the cooperation with BUCK, their professionalism, quality of lighting design and equipment delivered. We recommend them as a supplier that guarantees the quality in every aspect.’

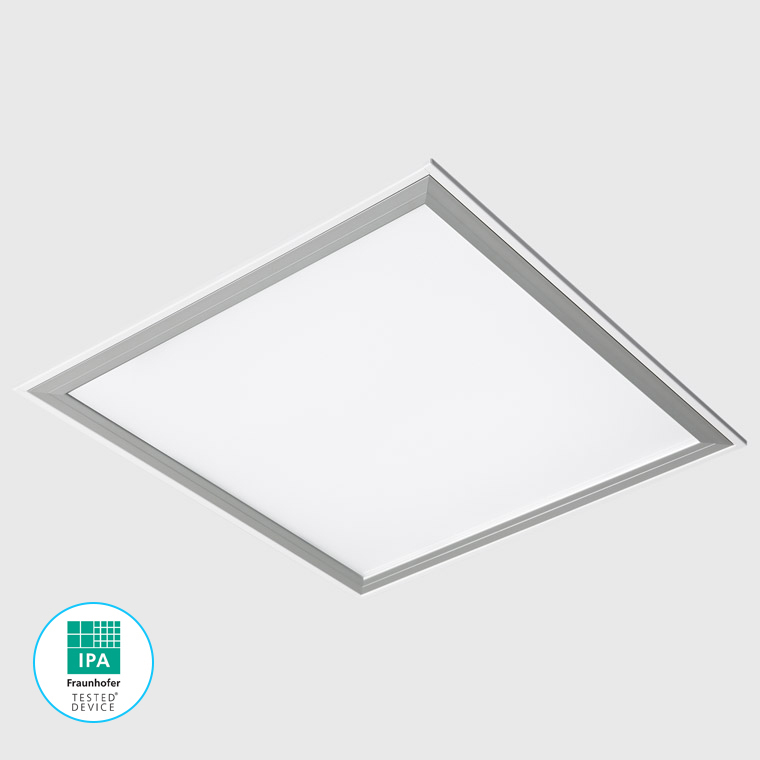

Healthcare

As a company present on the EU market, we are very satisfied with the quality of the CLEAN ROOM luminaire, technical support so all our client’s needs are fulfilled, as well as the additional support to the quality of the product with certificates such as IPA FRAUNHOFER. We have embraced the quality of BUCK team not only as partnership, but as an integral part of our team.

Pharmacy

Being the best in the industry means being surrounded with expert, reliable and credible associates. We have found one just like this in the company BUCK whose products and services we have been using for almost two decades. During this period, while developing our own production and following the highest industry standards, we placed very high demands regarding lighting equipment to which BUCK always had an appropriate response. Our trust is justified especially from the sustainability aspect, since BUCK is accountable for the energy efficiency of the entire lighting system in the company HEMOFARM.

Clean Room light fittings in

high technology era

We are witnessing the increase of overall knowledge in different sciences, concentrating on micro and nano particles. It raises the standards regarding facilities in which those sciences perform the research or production.

Not all industries need the same standards or same type of lighting. As a response to the market needs, BUCK lighting has developed a range of Clean Room light fixtures to cater for different needs of clean room applications.

For verifications, consultations and enquiries on the right type of Clean Room LED light fixture, feel free to .

Latest CLEAN ROOM LIGHTING APPLICATIONS

CLEAN ROOM SUNLIKE

Application: Healthcare (ICU, laboratories) Research centers, Industry (production plants) DYW circadian lighting ready, on request

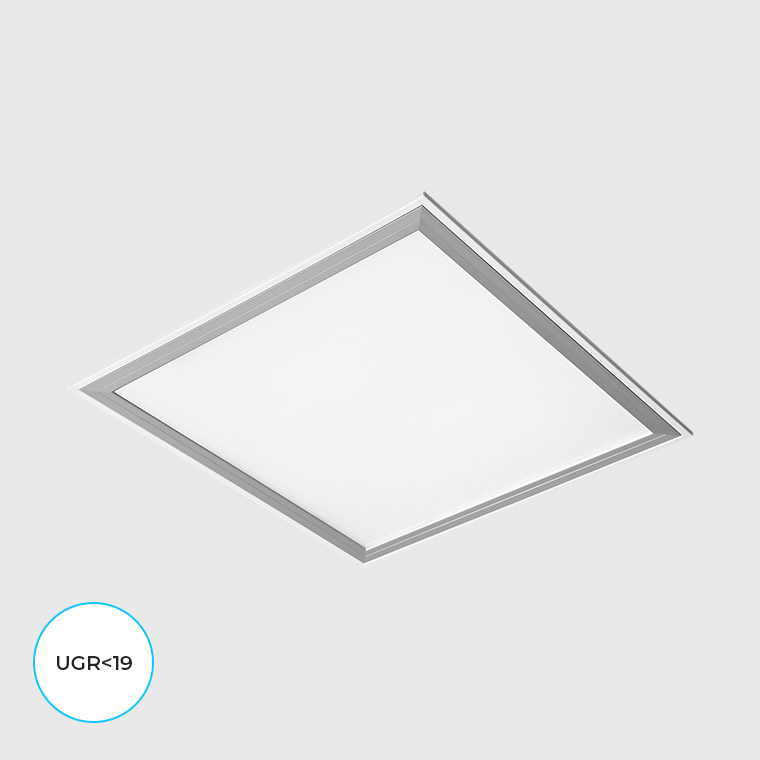

CLEAN ROOM CLA

Application:Healthcare (examination and treatment rooms, ICU, laboratories),

Industry (electronic, semi- conductor, microchip production plants)

CLEAN ROOM CLD

Application:Healthcare (sterile rooms)

Industry (pharmaceutical chemical and food production plants)

CLEAN ROOM CLA /C

Surface mountedApplication:

Healthcare (examination and treatment rooms, ICU, laboratories),

Industry (electronic, semi- conductor, microchip production plants)

CLEAN ROOM CLD /C

Surface mountedApplication:

Healthcare (sterile rooms)

Industry (pharmaceutical chemical and food production plants)

Specialized Clean Room lighting applications

CLEAN ROOM HB

Application:For mounting in exceptionally voluminous clean rooms h=8m; Industrial plants and warehouses with applied HCCP standard.

CLEAN ROOM CLA OT

Application:Healthcare (operational theaters, laboratories, Biotech and other rigorous hygiene spaces)

CLEAN ROOM CDP Ex

Application: Spaces with potentially explosive ambience Pharmaceutical & Chemical industry

CLEAN ROOM CLA /C Ex

Application: Spaces with potentially explosive ambience. Pharmaceutical & Chemical industry, Hangars

STREAM TEARDROP

Application: Clean & dry areas with laminar airflow. Micro-electronics industry, automotive batteries productionStandard Clean Room lighting applications

ETNA CR CDP

Application: Healthcare Industry*IP55 from above and IP65 below, for additional security

ETNA CR CDP CLIP IN

Application: Healthcare, Industry, CLIP IN suspended ceilings *IP55 from above and IP65 below, for additional security

ETNA CR DO

Application: General spaces with elevated hygiene level*IP55 from above and IP65 below, for additional security

ETNA CR DO CLIP IN

Application: General spaces with elevated hygiene level, CLIP IN suspended ceilings *IP55 from above and IP65 below, for additional securityQ&A

What kind of certificates do you have?

Our luminaires for clean room areas are certified by famous German institute Fraunhofer with ISO classes 1-9 and hygienic areas up to GMP classes A-C.

Where is your production facility located?

Our research and development dpt. and production facility are located in the capital of Serbia – Belgrade. Key strength of BUCK lighting product range lies in inhouse production, with traceable sequence of production processes and 100% control over the quality of components and final products.

Could you please explain complaints handling?

We offer standard 5-year warranty for complete products range.

We adhere to the procedure of handling complaints explained in point 5 and 6 of “5-Year Manufacturer’s Warranty for BUCK Products.” Link

Emergency light

All our luminaires for clean room areas are available on request with emergency modules of 1- or 3-hours autonomy, or luminaires could be connected to central battery system (CBS).

Lead time

Lead time depends on quantity. Our standard lead time is 8 weeks.

Due to shortage of components on the global market this lead time might be affected.

Light calculations service?

Lighting design center is one of our key strengths. We provide reliable service of lighting calculation for typical spaces to our partners free of charge.

Pricing

Pricing depends on the luminaire type, quantity, optics, lighting management chosen, additional equipment, realization date, etc. Net price per unit ranges from 150€ to over 400€.

Details of the luminaire surface from the clean room side (glass / frame)

Luminaire housing is made of metal steel sheet of different thickness depending on the luminaire family.

Diffuser frame is made of aluminum with two different types of optics:

1. DO – opal PMMA or opal PC on request

2. CDP – a triple layer optic consisting of:

• opal foil (to avoid noticeable dots of LED light sources)

• micro prismatic diffuser (contributes to glare control and the increase of visual comfort)

• 4mm thick tempered glass pane (resistant to cleaning agents and impact resistant, contributing to the easy maintenance, foremost cleaning)

How is the protected glass attached?

This depends on the product family as well. There are two different variants. Protector can be attached to the housing either via hidden screws or springs (inner and outer housing is opened with suction cups without using screwdriver).

Type of glass

We deliver 4 millimeters thick single-layer tempered glass.

Which luminaire housing colors are available?

Our CLEAN ROOM luminaires standard finish is with antibacterial epoxy polyester powder, RAL9003

Other colors are available upon request whereas additional cost might be applied depending on the quantity.

Applicable ceiling panel thickness

Our standard mounting hangers can accept ceiling panels that vary in thickness from 7 to 65mm.

We can adapt our hangers to accept even more than 100-millimeter-thick panel.

Dimensions

Our standard dimensions are available on the website (approx. 600×600/625x625mm or 1200x300mm).

For important projects we are ready to customize as per your requirements.

Degree of protection

All our luminaires for clean room areas are IP65 from bottom side.

Upper side IP depends on family (IP65 / IP55 / IP50)

Maintenance (from the false ceiling or from the clean room side)

Can you offer Ex protection luminaires?

Ceiling mounted luminaire only – Certified Il3G Ex nA llC T4 Gc i ll3D Ex tc lllC

Link

Can you offer walkable Clean Room luminaires?

Based on the provided information about the ceiling construction our CLEAN ROOM SLIM UP can adopt cover for accidental feet pressure on the luminaire in the walkable plenum. Link

Electrical connection

Without opening the luminaire, with fast connectors.

LED boards

We are using LED boards of well-known producers like Panasonic VS, MST, Tridonic, Phillips.