When designing lighting solutions for cleanrooms within explosive (Ex) zones, safety, efficiency, and compliance with stringent standards are paramount. Cleanrooms in Ex zones are specialized environments found in industries such as pharmaceuticals, biotechnology, manufacturing where even minor contaminants can compromise product integrity or safety. Additionally, Ex zones are areas where the atmosphere contains or may contain flammable gases, vapors, or dust in sufficient quantities to produce explosive or ignitable mixtures. The integration of cleanroom lighting in these zones requires meticulous planning to ensure both the purity of the environment and the safety of operations.

Key Considerations for Cleanroom Lighting in Ex Zones:

Compliance with International Standards: Lighting fixtures in Ex zones must adhere to global safety standards such as ATEX in Europe and NEC 500 or NEC 505 in the United States. These standards ensure that the lighting solutions are designed to prevent ignition of the hazardous atmosphere.

LED Technology: The use of LED lighting is preferred due to its low heat emission, energy efficiency, and long lifespan. LED lights reduce the risk of temperature-induced reactions in volatile environments and are cost-effective in terms of both energy consumption and maintenance.

Sealed Fixtures: Lighting fixtures in cleanrooms, especially in Ex zones, must be sealed to prevent the ingress of dust, vapors, and gases. This sealing also facilitates easy cleaning and decontamination processes, essential in maintaining cleanroom standards.

Luminance and Uniformity: Proper illumination is crucial in cleanrooms to enable meticulous work and inspection processes. Lighting solutions should provide consistent and uniform light distribution to avoid shadows and glare, which could hinder operations or inspection activities.

Emergency Lighting: Considering the potential risks in Ex zones, emergency lighting that can operate independently of the main power supply is essential. These systems ensure safe evacuation and continuity of critical operations during power outages.

Customization and Flexibility: The diverse nature of activities in cleanrooms across different industries necessitates customizable lighting solutions. Adjustable intensity levels and color temperatures can accommodate specific process requirements and worker comfort.

Incorporating these considerations into the design and implementation of cleanroom lighting in Ex zones not only ensures compliance with safety regulations but also enhances operational efficiency and product quality. As technology advances, lighting solutions continue to evolve, offering greater benefits and flexibility to meet the specialized needs of these critical environments.

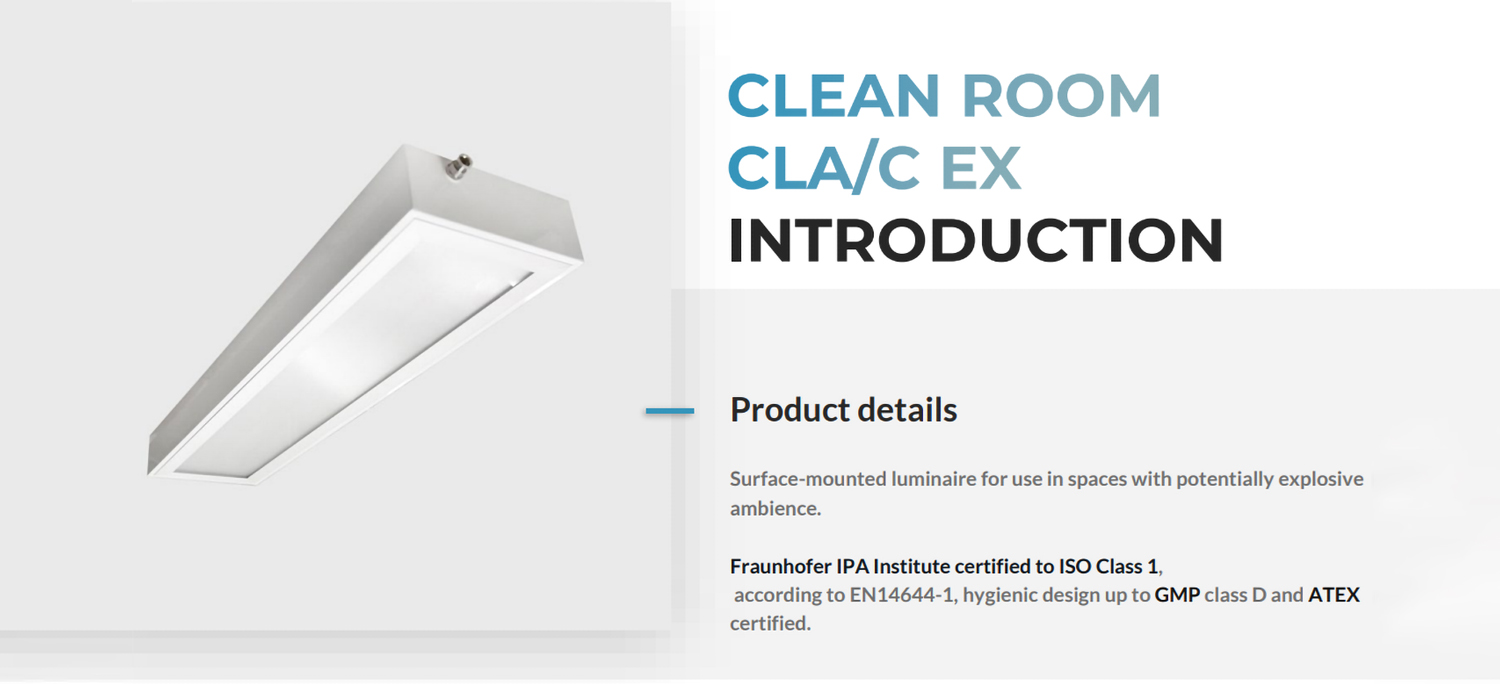

BUCK LUMINAIRE CLEANROOM CLA/C EX meet all these needs.