In the world of semiconductor manufacturing, precision is not just a requirement; it is the rule. As the industry pushes the boundaries of technology, creating smaller and more complex components, the need for controlled environments becomes increasingly important. Enter the world of cleanroom Teardrop luminaires in the quest for uncontaminated production spaces.

Why Cleanrooms Matter

Semiconductor manufacturing is a delicate dance of atoms and electrons. A single dust particle, invisible to the naked eye, can cause irreparable damage on a microchip, rendering it useless. Cleanrooms provide protection from such contaminants, and their lighting solutions are pivotal in maintaining this pristine environment.

The Cleanroom Teardrop Luminaire Advantage

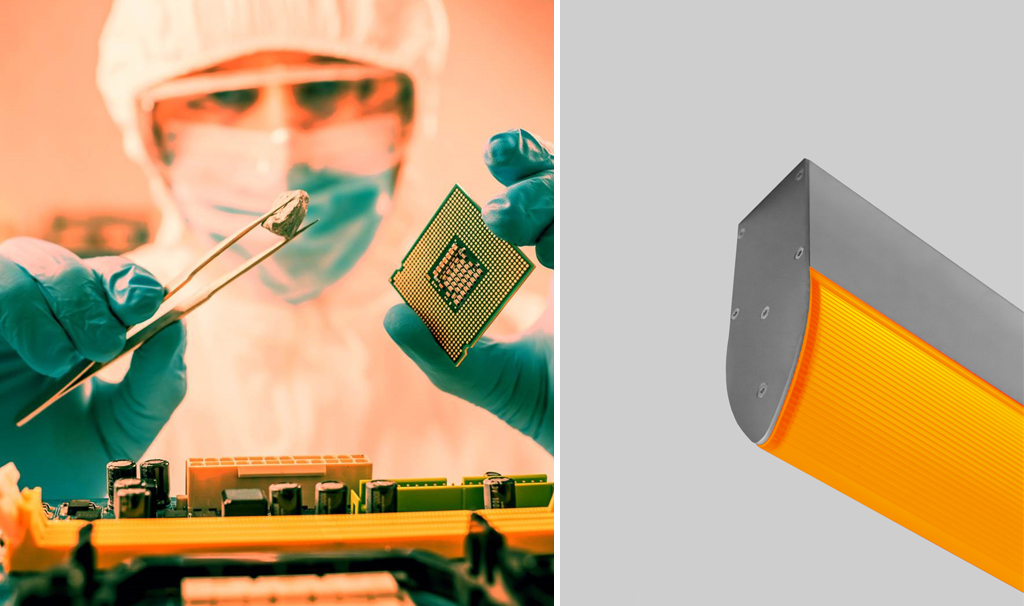

Cleanroom Teardrop luminaires are not average lights. They are engineered to meet the stringent standards of cleanrooms, particularly those adhering to the EN ISO 14644-1 classification, which is crucial for semiconductor processes and dictates the level of cleanliness and air changes.

These luminaires have numerous features that make them indispensable:

• Seamless Integration: Linear luminaire type allows for easy integration into cleanroom architecture. Surface-mounting between HEPA or ULPA filters with a specific teardrop luminaire shape ensures the flow of filtered air remains unobstructed.

• Dust Defiance: The smooth surface of teardrop luminaires disables dust accumulation, a non-negotiable feature in the semiconductor industry.

• Energy Efficiency: With the application of LED technology, these luminaires consume less power and offer a longer lifespan, translating to lower operational costs.

• Optimal Light Quality: The soft, glare-free light minimizes eye strain for employees, enabling focused and efficient work.

The selection of emission colour from LEDs is somewhat limited due to the nature of the semiconductor used in the manufacture. It’s important to choose the right colour to avoid any unwanted photochemical reactions that could compromise the semiconductor’s integrity.

Amber or yellow illumination is typically used in processes where photosensitive materials are involved. This special light colour is utilized to prevent unintentional exposure to damaging UV and blue light during the lithography, which is a crucial process for maintaining the quality and quantity in the production of the semiconductor components.

• Chemical Resistance: The materials used in cleanroom Teardrop luminaires withstand the chemicals often present in semiconductor manufacturing, ensuring durability and safety

• Service and Maintenance: Teardrop luminaires with features that allow easy tool-free service, additionally saving time and ensuring the safety of maintenance personnel.

A Bright Future

As the semiconductor industry continues to evolve, the demand for specialized lighting for their production will grow. The role of lighting in this context goes beyond mere illumination. It is about paving the way for the microelectronics that power our future.

In conclusion, the cleanroom Teardrop linear luminaire is more than just a fixture; it is an important component in the intricate ballet of semiconductor manufacturing. It stands as a testament to the lighting industry’s unwavering commitment to quality and innovation – a silent guardian of the microscopic worlds we continue to explore and expand.