Many users of spaces with installed LED light sources have encountered problems when they wanted to replace existing LED sources (LED modules) in fixtures for various reasons. They simply could not find LED sources that fully matched the existing ones in the fixtures, so they were forced to replace the entire fixtures. However, this is often not a solution either, because those specific fixtures may no longer be produced, or the light effect from the new replacement fixture is not identical to that of the originally installed ones. In any case, in such a situation, the user is most often forced to chase the fixture manufacturer from whom they initially bought the fixtures, and it can be figuratively said that they become “slaves” to that manufacturer when it comes to maintaining those fixtures. When fixtures with fluorescent, metal-halide, HPS, and other sources were used, this was not a problem because the user, or the maintenance service, could easily buy these sources on the open market. Unfortunately, this has not been the case with LED light sources for many years.

Often, fixture manufacturers have their own production of LED light sources (LED modules) which they only produce and use for their fixtures, and these cannot be purchased anywhere else. The global market realized this, which led to the creation of the Zhaga standard.

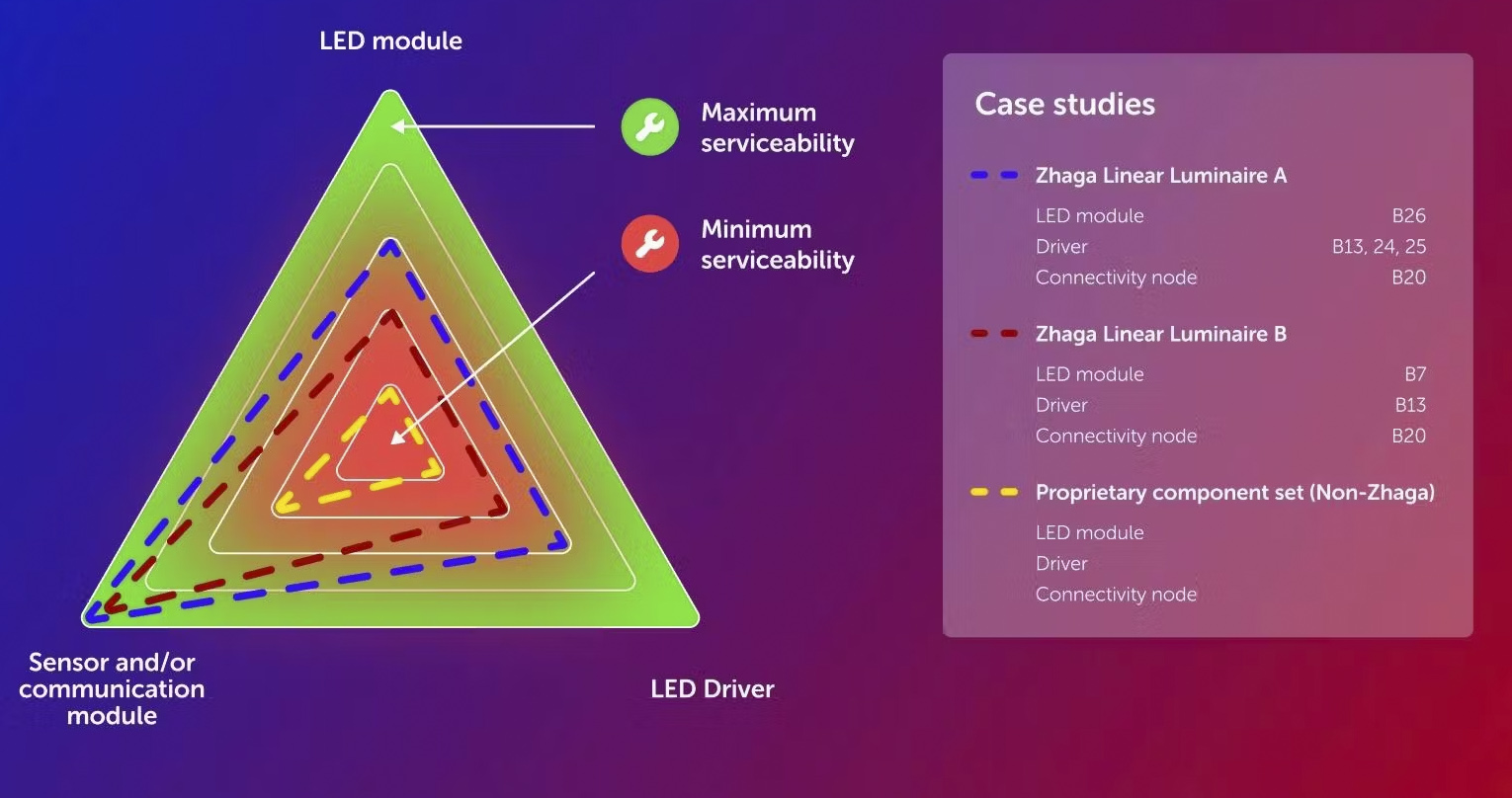

The Zhaga standard was established by an international consortium consisting of many leading companies in the lighting and electronics sectors. It was founded in 2010 to enable the simple replacement of LED components from different manufacturers. This standard covers various aspects of LED lighting, including their dimensions, photometric, and electrical characteristics. The components made according to the Zhaga standard always have the same dimensions, the same hole layout for mounting, and the same terminal layout for connection. All of this allows for easier integration and replacement of LED modules in fixtures, helping users to have a broader choice of compatible components. In short, if you decide to purchase fixtures with LED modules and drivers made according to the Zhaga standard, you are getting a product with which you will not have maintenance problems.

LED modules and drivers made according to the Zhaga standard indeed cost more than those not made according to this standard. This is automatically reflected in the price of the fixtures, but it is important to be aware that the advantages users gain with this are manifold. Some of them are:

– Easy replacement and maintenance – End users can easily replace lighting components without needing to modify the entire system, reducing maintenance costs.

– Increased flexibility and choice – Standardization allows users to choose from a wide range of products from different manufacturers.

– Improved light efficiency and performance – LED fixtures with components made according to the Zhaga standard often have high energy efficiency, which can result in significant savings on electricity costs. Additionally, standardization ensures a high level of lighting quality.

– Durability and reliability – The Zhaga standard ensures that components undergo strict quality and reliability tests. This automatically means that such products will last longer and operate without issues.

– Sustainability – Standardization of components reduces waste, as components can be replaced individually without having to replace the entire fixture. Additionally, energy-efficient lighting contributes to reducing overall energy consumption, which positively impacts the environment.

The professional recommendation for all users is to carefully consider whether to purchase a fixture next time without checking if the LED modules and drivers are made according to the Zhaga standard.